What is Solid Wood Flooring?

Solid Wood flooring is a type of timber flooring comes with a single plank of natural timber. The quality of the solid wood flooring is indeed depending on the sawing method of the logging. The timber boards produced from different type of sawn will determine the dimension stability, pattern appearance and costing for the final products.

There are three different ways that timber board can be cut out of a log to produce solid wood flooring. These include plain sawn (or flat sawn), quarter sawn and rift sawn. Each method has its own advantages and disadvantages. Normally, plain sawn and quarter sawn are the method to use in produce solid wood flooring.

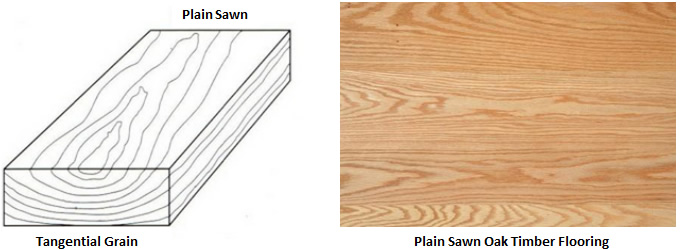

Plain Sawn

Plain sawn or flat sawn is the most common method of sawing and consequently most solid timber flooring is produce by plain sawn. This is the most straightforward way to cut rectangular-profiled timber boards by cutting a log lengthwise with a series of parallel cuts. Plain sawn provides excellent yield, widest boards and least waste. Therefore, it is the most economical method.

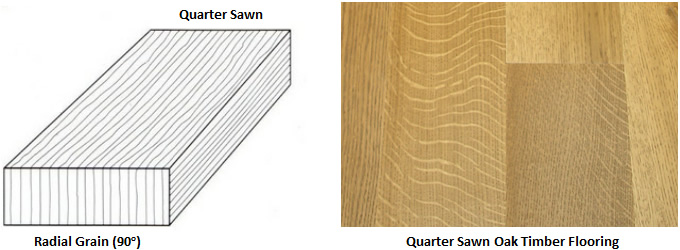

Quarter Sawn

Quarter sawn is a method that logs are cut into quarters then sawing it perpendicular to the growth rings. The timber boards sawn thus are of radial grain. When looking at the end grain, the annual growth rings will be at 90 degrees to the face. One disadvantage of quarter sawing wood is that it leaves some scrap. This typically makes quarter sawn wood more expensive than plain sawn wood.

Rift Sawn

Rift sawn is quite similar to quarter sawn. Each board is cut perpendicular to the log’s rings, so each board has more of uniform appearance because of the similarity of grain. The angle of the cut is changed slightly so that fewer cuts are parallel to the medullary rays, which are responsible for the flake effect. Rift sawn provides very poor yield and leaving lots of scraps. Its low produce yield and high scraps typically make rift sawn more expensive then plain sawn and quarter sawn. This is why rift sawn is not a common method to use is produce solid wood flooring.

Wood Grain Appearance

Plain Sawn

Plain Sawn timber flooring is easily recognized by this cathedral (Gothic arch) effect in the face of the timber board. The end grain will have semi-circles or so called tangential grain.

Quarter Sawn

The grain pattern on the quarter sawn timber flooring surface is straight grained with the significant medullary ray (flake). The end grain is 90 degrees or so called radial grain.

Rift Sawn

Rift Sawn timber flooring maintaining the same straight grain appearance as quarter sawn but exhibits less medullary ray effect on the surface. This is because the angle of cuts is change slightly so that fewer cuts are parallel to the medullar ray. The end grain is a 60 degrees appearance.

Dimensional Stability

Wood is an anisotropic and orthotropic material. The properties of the wood vary along three mutually perpendicular axes: Longitudinal, radial and tangential because of to the orientation of the wood fibres and tree is increase in diameter when it grows.

Anisotropic

Exhibiting different properties along different axes; in general, fibrous material such as wood are anisotropic

Orthotropic

Having unique and independent properties in three mutually orthogonal (perpendicular) planes of symmetry; 3 special case of anisotropy

The longitudinal axis is parallel to the fibre (grain) direction, the radial axis is perpendicular to the grain direction and normal (radial) to the growth rings, and the tangential axis is perpendicular to the grain direction and tangent to the growth rings.

Dimensional changes in the longitudinal direction are between 0.1 and 0.2% and are of no practical significance; meanwhile, tangential shrinkage (varying from 4.4 to 7.8% depending on species) is twice that of radial shrinkage (from 2.2 to 5.6%).

By referring back to the details of sawn method and wood appearance that discuss on paragraph above, Plain Sawn is tangential and Quarter is radial. Therefore the solid wood flooring with quarter sawn is stable than plain sawn solid wood flooring